The compressor came with a 2hp motor wired for 230v but it was capable of running on 115v, so my first job was to rewire it to make sure it worked on 115v. Then after cleaning it up a bit and changing the pump oil, I timed how long it took to pressurize the tank from 0 to 110 PSI. Eight and a half minutes. Hmm, that seems a bit long. Is that normal? I don't know.

I then took everything off the tank and gave it a good scrubbing. The tank was made in 1977, so it isn't a really old compressor, but still vintage enough for me.

An internal inspection of the tank showed remarkably little corrosion. Much of the original mill scale finish is still on the steel. Cool. The water droplets were from me rinsing out the tank.

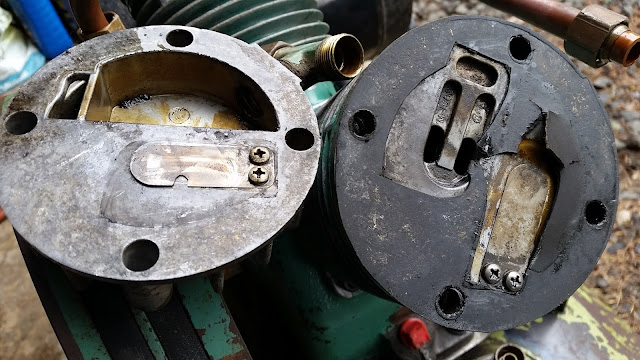

Now to see about the long pump-up time. I wasn't sure if 8 minutes was longer than normal for filling the tank, but off came the heads just to take a look.

We have a problem Houston. One gasket was blown out. The valve also has a small chunk missing, but that doesn't affect performance. I think I might get new valves at some point though.

I made a new gasket, which should help a bit.

Everything is back together, and $32 worth of new pressure regulator, hose and safety valve are installed.

And the best news, the 0 to 110 PSI pump-up time was reduced from 8.5 minutes to 2.5 minutes with the new head gasket.

I think I'm going to like my new $82 air compressor.

Update 2/21/2019: Below is a photo of the serial/model number tags on the compressor. The serial number of the compressor assembly is 285246, and the model number looks like "20CV20PC" but the second character is questionable. The actual pump serial number is CV0020099.

Update 8/6/2019 - Below are a couple photos of the motor data plate, showing the wiring and such.

13 comments:

I just picked up a very similar looking Porta-Champ compressor. Mine came with a smaller motor and I'm thinking about increasing the HP and pump RPM to get more air flow.

What's is the model number on yours (I think it's on the small name plate near the pump)? Does the 2 hp motor run at 3450 rpm and what's the motor pulley diameter? Thanks!

I've added photos of the serial/model number tags. Model number looks like 20CV20PC but I'm not 100% sure. The motor pulley is about 2 inches in diameter and RPM is 3425.

Hi. I have this same compressor and I believe same motor. My motor no longer has any identification or wiring diagram. There are four wiring posts numbered one through four, and currently two internal wires are on post 3, with the two from the socket coming in on 1 and 4. Could you tell me how you wired for 115v? Thanks in advance

I've added a couple photos of the motor data plate and wiring diagram on the plate. Looks like mine has 7 wires inside (I haven't pulled to plate off to look though). The motor is dual voltage, fwd/rev rotation, single phase.

Thanks so much, for the reply and for the great blog post.

I’m hoping I can bug you for a bit more help. My motor is up and running and the tank is now filling. The trouble I’m facing now is my lack of understanding of the plumbing on the output side of things. I wish I could post photos to show you what I’m referring to. When the tank gets to approximately 70 psi the air starts discharging rapidly at the output. There is a three way valve coming out of the tank. The side closest to the motor has a bolt head and is fastened in. The side facing outwards is the 1/4” npt connection for the hose. The middle output which faces towards the belts has a threaded insert with a hole in the middle. That hole is where the air is being released and seems to be preventing a full charge on the tank. On another note, reaching 70psi happened very quickly, just over a minute.

Thanks again in advance!

The threaded insert you refer to sounds like a pressure relief, and it is popping open at 70 psi. Pressure reliefs usually have a pin poking out the center with a ring that you can grab and pull out to test the relief valve, but your threaded insert may be a different type of pressure relief than what I'm familiar with. My compressor did not have a pressure relief when I bought it (very dangerous if the pressure switch fails on) so I put one on that is supposed to pop open at 150 psi. I have the pressure switch set to about 125 psi.

Much appreciated! I think I’ll find a local compressor repair shop and get a tube up/education. I’d like to feel safe knowing that it’s set up well and working before I put any strain on this old unit. All the best!

Where did you get the gasket to buy

I cut it from gasket material. I guess I should have said that.... Thanks for the comment.

After looking at it carefully I figured that. Good job.

Can you measure the electric motor pulley diameter. I bought a compressor without the motor. Thanks

2-1/8" OD on the motor pulley, 10-1/8" OD on the compressor pulley.

Post a Comment