For several years now I've been using a Come-Along to drag old relics of tractors into my dump trailer. It gets old real fast, so I decided a couple of months ago that I need a winch. The one big downside of buying a winch is the task of fabricating a mounting location on the trailer for the winch. My first attempt was less than stellar. I thought I could weld a 1/4" steel plate to the top rail and bolt the winch to the plate. Sounds easy enough, so that's what I did.

ItsNotJunk

Friday, July 11, 2025

Saturday, June 14, 2025

1943 Dodge WC51 Windshield Wiper Repair

This will be a short posting. The driver's side wiper blade came off its arm when I was washing the truck several days ago. I took a look at things today and found that a small bracket on the end of the arm has rusted through. No problem, I can fix it. Yes, I'm cheap. Or maybe I don't want to take the time to try and find and order a replacement, pay an exorbitant amount for shipping, then have to wait a week or two for it to show up. But mostly it's that I just like the challenge.

Thursday, June 12, 2025

1943 Dodge WC51 Charging System

So, the blog I did a couple days ago regarding brakes mentioned that brakes are usually a problem on old vehicles that will need serious attention. Another very normal problem is the charging system. This truck has a 12 volt generator and regulator. I think it came from the factory with a 6 volt system but somewhere along the way it was converted. At least it still has a generator. I don't like it when people put in one of them new-fangled alternators in old vehicles, but I digress.

With the charging system inoperative, my usual first step is to check if the regulator is working, so I pulled it off the truck and opened it up. After a few minutes of looking things over, I spotted what looked like a broken wire. It was quite difficult to see, but yes, there it was. A broken wire barely thicker than a human hair. Ok, so maybe it is several times thicker, but it's still whisper thin. The photo below is the repair I did to it. I soldered in a larger solid strand wire to splice between the end of the broken wire and its terminal. The two photos below show the white wire I added. If you look close at the blow-up photo and squint real good, you can kinda maybe see the thin wire soldered onto the end of the bigger wire.

Yes, most people would have just gone out and bought a new regulator, but where's the challenge in that? (sticker shock: I just looked online and the cheapest one on eBay is $135, NAPA is $190-$240)

Tuesday, June 10, 2025

1943 Dodge WC51 Fuel Tank, Gauge and Sender

The fuel tank was out of this truck when I purchased it. The previous owner had the tank cleaned and the inside coated with a sealer, which was a good thing, as I then didn't need to mess with it at all. Just slap the tank in and hook it up. Or so I thought...

Monday, June 9, 2025

1943 Dodge WC51 Master Cylinder Repair and 2025 Tractor Show

Ah yes, brakes. One of those systems on an old vehicle that usually needs a lot of work. And this truck's brake system falls into that "usually" category. I figured I'd try the easy three-step fix first. You know, the Dead Dodge Garage (youtube) method.

Step 1 - see if brake pedal goes to the floor

Step 2 - fill the master cylinder with brake fluid

Step 3 - pump the brake pedal until something changes - hopefully the pedal starts to get firm

With this plan in mind, I'll dive right in. The first order of business is to get access to the master cylinder (MC). On virtually all modern vehicles, it's under the hood and in easy reach to allow for servicing. This truck? Nope. It's under an access panel in the cab floor. Fortunately the panel was held in with just "a few" bolts. Eight to be precise...

Tuesday, May 27, 2025

1950 John Deere BN Valve Adjustment

John Deere manages to make things difficult. Even the most basic task of adjusting the valves was way more difficult than it had to be. The carburetor float bowl is in the way of getting the valve cover off, so I had to drop the bowl. The large stem poking down in the photo is what the bowl nut threads onto. That stem is still in the way to get the valve cover out all the way but there was just barely enough room to do the job. I suppose since the carburetor on this tractor is not the correct one, it just might have been easier if the right carb was in place, but I doubt it. Most of these DLTX carburetors are very similar in construction.

Friday, May 2, 2025

1950 John Deere BN Brakes - Can You Say Scope Creep?

The brakes on this tractor did work but not very well. Neither brake pedal would spring back like they're supposed to after releasing the brake pedals. Also, the right hand brake was adjusted too tight and was dragging some, so my first order of business was to try and loosen the right side adjuster. It was stuck and did not want to budge one little iota. Ok, so let's pull the brake drum off and see what's going on. That was the first level of scope creep, removing the drum, and it was an hour-long endeavor but the drum is finally off. Come to find out though, that's the least of my worries.

Wednesday, April 23, 2025

1950 John Deere BN First Wash and 3Pt Hitch Repairs

It was time to break out the pressure washer and get the growth off the BN today. Here's an after shot.

Wednesday, April 9, 2025

1940s Blue Diamond Generator AKA Gas-O-Lectric Plant AKA Pioneer Gen-E-Motor

I'm not sure what the official name for this generator is, but I'll call it a Blue Diamond Generator since that is the name at the top of the tag. All three names in the title are on the tag in various places, so I guess folks can take their pick as to which one to use.

Saturday, April 5, 2025

Seagull ST3601 Manual Wind Watch "Kit" from AliExpress

This is a first for me. I ordered parts from AliExpress to build a watch. I know everything is made in China, but I wanted to see what the quality was like for things that are so very cheap. I bought a Seagull ST3601 hand-wind movement with a swan neck regulator (cool!), a stainless steel case with sapphire crystal and mineral glass display back, a black dial, two sets of hands (black and white) so I could have an option if I didn't like one set, and a brown leather watch strap.

Friday, March 28, 2025

1950 John Deere BN - Narrowing Rear Wheel Width

This tractor's rear wheel width is 74 inches, outside to outside. My little dump trailer is 72 inches in width between the sides. The more astute may see a problem there. I measured the wheel width before I bought the tractor, so I knew what I was getting myself into, although this job ended up being a huge endeavor. As I mentioned in the first blog posting of this tractor, the previous owner graciously offered to deliver the tractor to me, so I didn't have to do this painful job away from home. That would have been horrible, now that I know what it took to get the job done.

This first photo is of the left side. If you look closely at the nuts relative to the round opening, the nuts barely (if at all) have room to rotate, and there's a small lip that makes it so a socket can't get all the way onto the lug nuts. This may be a problem. [I later found out that this small inner lip is actually a register for the center splined hub to fit into - more on that later.]

Friday, March 14, 2025

1950 John Deere BN - Cleaning the Gas Tank, Fixing an Oil Leak, Repairing the Voltage Regulator, Finding and Fixing A Hydraulic Leak, and a New Ammeter

The gas tank on this tractor is filthy with rust and crud. It won't run more than a few minutes before the tank's outlet is silted over with junk, so it's time to take off the tank and do some deep cleaning. It's not as easy as it sounds though. The tank is bolted to the hood as a unit and the steering shaft also goes through the hood so the shaft has to come out. The steering wheel needs to come off to get the shaft out. A woodruff key is in the end of the steering shaft to key the shaft to the steering wheel. The woodruff key was so rusted in the shaft slot that I ended up shearing off the key with a hammer and cold chisel. Normally these woodruff keys slide out of their slots fairly easily.

Friday, February 28, 2025

Changing A Tire The Hard Way (and Replacing the PTO Shaft and Cut-Out Relay, and Fixing the Carburetor) - 1941 Ford 9N

The day I showed up to buy this 9N, the previous owner told me he was filling one of the rear tires with air on the tractor and the rim let go. As in, a section of the rim flange blew out. See it there? Kinda hard to miss. That was back 4-1/2 months ago. I figure it's time to tackle this little problem, as the tire obviously won't hold air the way it is and I can't move the tractor very easily.

Tuesday, February 11, 2025

When Will The Madness End - Several New Projects: Wisconsin, Briggs & Stratton and Other Engines

I have tractor projects coming out of my ears and what do I do? Buy two new projects (update - there are more, read to the end). Oh boy. At least they're small projects, and they were too cheap to pass up. Ten bucks for two Wisconsin single cylinder engines.

Saturday, January 18, 2025

First Time Fiddling With The 1950 John Deere BN - First Issues: Water in Oil and Gas Tank, Corroded Magneto Points, Stuck Throttle Lever, Stuck Choke, Broken Carburetor (and Float Repair), and Stuck Clutch

My newly acquired tractor made it home yesterday afternoon. The person I got it from owns a tractor rental company and he kindly delivered the tractor to me on his mighty-nice roll-back hauler. It was a big rig to fit down my cramped driveway. As you may or may not have noticed, the Massey Harris Pony hasn't been unloaded from my dump trailer yet. I got that tractor a month ago, although Christmas goings-on were in there also.

Monday, January 13, 2025

1957 Greenerd 3 Ton Arbor Press No. 3

When glancing through random online Craigslist/FB Marketplace ads, I occasionally run across something I need. Yes, you read that right, "need." This time probably wasn't one of those times, but this new addition is something I've wanted. It's a Greenerd 3-ton arbor press. What's an arbor press, you say? When these things were invented over 100 years ago, they were used to press arbors into things, like pulleys or whatever. An arbor is just a round rod like an axle or spindle, and it gets pressed into something like a hub or pulley. Thus the name "arbor press." You can probably guess these presses are used for a multitude of jobs besides just arbors.

Friday, January 3, 2025

1950 John Deere BN "High Clearance" and State of the Collection

The tractor situation is pretty normal. A week goes by and Yet Another Tractor (YAT) shows up at my doorstep. Ok so this one isn't exactly here yet but I have paid for it and the place that has it will deliver it in a few days. Incoming is a 1950 John Deere BN. The "N" in BN signifies a narrow front, also called High Clearance because it sits a little higher than a normal John Deere B. JD accomplished that by putting on larger wheels/tires. The regular B had 38 inch wheels in the back and the BN got 42 inch wheels (although 38 inch wheels were an option). The BN also got a single front wheel rather than the normal tricycle front with two close-together wheels.

Saturday, December 14, 2024

1951 Massey Harris Pony

I could go on and on about how I need to stop looking at want ads for tractors, but we all know how that goes. So, without further ado, may I present the newest addition to the herd, a 1951 Massey Harris Pony.

Wednesday, November 6, 2024

1943 Dodge WC51 Hood and Transfer Case Linkage Repairs

There's a central hinge on the hood of this truck. Each side can open up to work on that side of the engine bay. Problem is, the hinge pivot on the back edge of the hood had broken off at some point and the hood halves no longer stay propped up. It's no wonder the pivot broke, as it's just the end of the sheet metal hinge that had been formed into a round peg. Here's a photo of the front hinge pivot for context.

Tuesday, November 5, 2024

1943 Dodge WC51 Map Table

When first looking at this truck at the previous owner's place, he mentioned, "It even has a map table." He tried to pull out a piece of wood from under the glove compartment but it was stuck. Well isn't that cool though, I thought to myself. With the truck at home, I finally did get the piece of wood to budge, I found out it was pressed board, not an original piece, so it was time to make a replacement. I found a piece of 1x6 pine in the basement and set about cutting it up into strips. I decided to make the strips two different widths just to make things interesting.

Monday, November 4, 2024

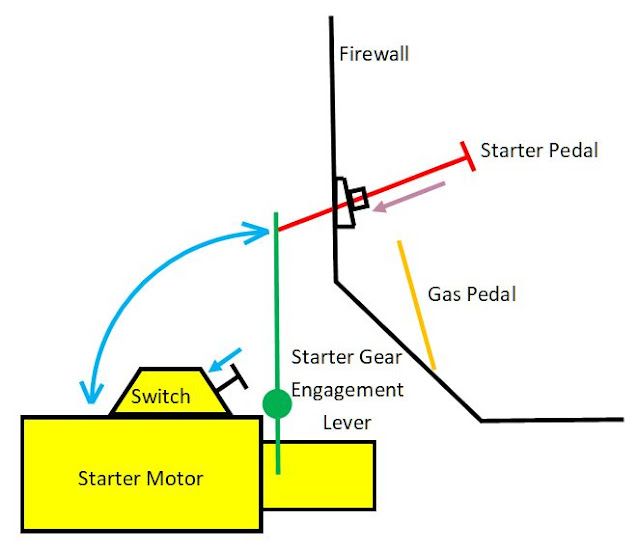

1943 Dodge WC51 Starter Pedal Repair

This truck has a unique starting system. You don't just turn the key to the start position and have the starter motor happily crank away. Oh, no. You push on a long rod or pedal with the tip of your right foot, press down firmly, and then the starter motor comes to life. With your foot on the pedal, it will take some coordination to use the heel of your foot to apply some throttle from the gas pedal while still pressing the starter pedal. It takes a bit of practice. The truck is supposed to have a manual throttle cable in the cab so as to allow application of some throttle without having to get your foot onto the gas pedal, but mine is missing. It's only $35 (!) to get a new throttle cable. Someday.

Wednesday, October 30, 2024

1943 Dodge WC51 Speedometer/Odometer Repair and Battery Tray

I really should work on something like the Farmall C that needs a lot more help than this truck does. I actually did move the Farmall off the lawn and into the garage today though (I'm sure to the delight of my wife), so it will be easier to work on it. I got a couple large bearings for the front pedestal so I might have enough parts to get the front wheel assembly put together and mounted on the tractor. That will make it so much easier to move it around in the shop. But enough of that, back to the truck.

The speedometer cable had been disconnected from the speedometer when I got this truck. I took a look at the end of the cable and the square drive piece was missing, like it had been twisted off. I felt up behind the dash and found the stub still in the speedometer. I tried to turn the spinny part of the speedometer (not sure what else to call it, the part that is driven by the cable) but it wouldn't budge, which is precisely why the square drive had been twisted off. I pulled the speedometer out of the dash and decided to delve into it. Without too much difficulty, I got the spinny part of the speedometer to turn so I chucked up the stub of square shaft from the cable into a drill motor and started things spinning. The speedometer worked but the odometer and trip meter did not.

Sunday, October 27, 2024

1943 Dodge WC-51 Repairs and Updates

A couple of weeks ago I was happily working on my "new" Farmall C kit (basket case, really) project, but then the brakes were put on it when this WC showed up out of the blue. Of course I had to do some fiddling with the new-new project, since the Farmall is merely an old-new project now. I got several things done today on the truck. The first thing I worked on was to oil the flapper doors on the little heater cube under the glove compartment. The heater isn't hooked up under the hood so I don't know if the heater core leaks, but I did get all the flappers working. Do you see it under the map table in the photo below? No? It is peaking out there. And that map table is made from particle board, so obviously it's not original. I'll make one from solid wood at some point.

Saturday, October 26, 2024

1942 License Plate Restoration

I picked up a vintage license plate on eBay for the 1943 Dodge WC51. The plate is 1942 and the truck is 1943. In Washington state, and many other states during WWII, steel was in short supply, so the normal yearly issuance of license plates was curtailed for 1943 and most of 1944. That means a 1942 license plate is correct for my truck. I was fortunate to find a plate specifically for a truck, as all other 1942 plates on eBay were for cars. In fact, doing an online search, I couldn't find a photo of any other 1942 Washington truck plates other than this one. These first two photos are the condition of the license plate I got. It's not ideal by any stretch of the imagination, but I think I can work with it.

Monday, September 30, 2024

1943 Dodge WC-51 Weapons Carrier

When will the madness stop? Ok, I know that looking on Craigslist and FB Marketplace were the downfall of my last two tractor purchases, but this new acquisition didn't happen because of my perusing the want ads. No, this deal was thanks to a fellow tractor club member. I guess I never should have joined that club. See where it's gotten me? Four tractors bought from club members, five if you count one that's been sold. And now I have me a Weapons Carrier.

What's that, you say? Weapons Carrier? Uh, is that legal to own? Yes, it is. And little did I ever think I needed or wanted one. But there's a story here. "Yes, of course there is," you say. Well, sit back and have a listen. So I have to go back four years. I joined the tractor club in 2020, right smack in the middle of Covid. I joined because I'd bought an aluminum can crusher powered by a 1917 2-1/2hp hit and miss engine. The gent I bought it from, Buck, said that the person who buys this can crusher should really be in the club, as it was kind of a mainstay of the club's shows. I told him, sure, I'll join, as I had a little Gibson tractor (yes, only one old tractor then) in the garage at home, and I was buying Buck's John Deere LA tractor also (another deal I couldn't pass up). I'd never been in a tractor club before. Should be fun. And now see where it's gotten me. But I digress.

Fast forward several years, and at one of the club shows, another member said to me he's always wanted a Gibson like mine. That planted the seed. I didn't have a real connection to the Gibson, so that thought of selling it to him began to percolate in the back of my mind. Fast forward to earlier this year (2024) and the same guy said he was going to sell his old WWII army truck. I innocently asked how much and he said, "I was thinking 35." Hmm, 35, 35... Thirty-five what? Hundred? Thousand? So I just had to ask, to which he said, "$3500". Wow, that seems cheap, I say to myself. I told him I was somewhat interested, and maybe we can work out a deal on my Gibson and cash. A little time went by and we came to an agreement. So now I'm down one Gibson and up one Weapons Carrier.

Sunday, September 29, 2024

1941 Ford 9N Tractor First Start

This blog posting is an update on the Ford 9N that came home with the Farmall C recently. I worked on this tractor for a few hours and got it running. There were a couple of things going on. First, the starter didn't work when I put in a battery. Second, once I'd removed, tinkered, and reinstalled the starter a couple of times and got it going, there was no spark. I read online that the easiest way to fiddle with the points in the distributor is to pull the distributor..... What?! Ok, I kind of get it, as the distributor on the 9N, 2N, and early 8N is mounted on the front end of the engine, under the water pump. Yeah, Ford did not have a better idea that day, and they realized it and put the distributor on the side of the later 8N's engine. It's hard to see in the photo below but the distributor is in there somewhere. Super fun to get to. Yep.

Monday, September 23, 2024

You Know You Have A Problem When.....

Umm, how do I begin. After previously lamenting how many tractors I have, I go and get two more. Two, you say? Yes, two. Really though, it's not my fault. I said no. I did. But then the seller did the dastardly deed and said those magic words, "Package Deal". I won't waste anymore time in words. Here's a photo. Ain't it a sight to behold?

Tuesday, September 10, 2024

1955 Ferguson TO-35 Body Work - Part 2

Today I finished the second side panel on the TO-35 hood. It was almost as enjoyable as the first one... It did take less time, but then getting things all put together was a lot more difficult than I would have expected, but I'm getting ahead of myself. This first photo is the right-side panel before doing any work to it. I wonder, is it sacrilege to use a John Deere tractor as a table for a Ferguson tractor part?

Friday, September 6, 2024

1955 Ferguson TO-35 Body Work - Part 1

Oh how I love doing automotive body work. Not. Give me a wrench any day. But ya gots to do what ya gots to do if you're too cheap to pay someone to do it, and the TO-35 hood's side panels need some attention. And it's about time. This poor tractor has been relegated to the "back 40", i.e., behind the garage, for way too long. And I just looked when I posted anything about it - a year ago. Ok, I didn't need to know that. But it's actually not as bad as it sounds. It was a whole two months ago that I did start working on the hood. I got it pulled off and disassembled. Then other things came up. Like more tractors, but I digress. So, here's the problem to tackle. Someone in the distant past used a hot wrench (oxy-acetylene torch) to hack off the bottom inch or so of the hood's side panels, I presume to mount a front end loader, and I am going to attempt to rectify that blunder.

Monday, September 2, 2024

1925 Economy Hit & Miss Engine Repairs/Tune-up and 1939 Turner Hay Press Tensioner Handle

A guy in my tractor club owns this 1925 Economy 1-3/4 hp hit & miss engine. It hasn't run right for a couple years now and at the recent county fair, we started smelling gas, and I speculated it might have a tank leak. I offered to take a look at the engine, brought it home after the fair and sure enough, the soldered outlet on the gas tank had failed. I pulled the tank and re-soldered the joint. Of course, to get the tank out, the wheels and wooden base had to come off. That meant enlisting the help of the engine hoist, as the engine is probably in the 300+ pound range.

Wednesday, August 28, 2024

1951 Baird Beaver "New" Carburetor

Yeah, the quotes on the word "new" means it's not a new carburetor, but it's new to me. The carburetor that came on this tractor is a Stromberg UR-3/4, which in and of itself is something a little unique. Someone on the Baird Beaver forum took one look at a photo of it and said it was probably from the late 20's/early 30's. Wow, a 90-year-old carburetor. Here's a photo of the Stromberg. If you'll note the air intake of the Stromberg, it is facing directly at the muffler, so an air cleaner won't even fit on it. This carburetor also has a small intake manifold between it and the engine block, which isn't a stock piece for the Wisconsin AKN engine on a Beaver.

Monday, August 12, 2024

1936 John Deere BO Welding Fuel Cap Shields

The B "Orchard" tractor came from the factory with small shields for the air intake and the two fuel caps on the hood, so low-hanging tree branches had less of an opportunity to snag on stuff. My tractor's hood had the air intake shield but the two fuel cap shields were not on the hood, which doesn't make much sense, as the BO hood always had all three shields and the BR hood always had none. Fortunately two proper shields came with the tractor.

Today would be the day I either ruin the hood or come away with a finished product that looks somewhat decent. This first photo below shows the shields. They look like small air inlet scoops but the openings will be facing rearward. The openings are a little dented up so the first job is to try and straighten them.

Thursday, August 8, 2024

John Deere LA and BO Repairs

My 1941 JD LA has a battery but the only thing it is hooked to is the starter. Well, and the generator, but I'll get to that. The engine has a magneto so if I had a hand crank, I could start and run the tractor without a battery. The tractor did come from the factory with lights but the front one is currently missing and the rear one is not hooked up. The ammeter is also not hooked up, so yesterday (8/7) I remedied that. I wired up everything and installed a light switch. But it's not any ordinary light switch. Oh no no no no no. Let me explain.

Old tractors like this LA have a very rudimentary charging system. The generator has what's called a cut-out relay (not a voltage regulator), and its only job is to cut any voltage draw from the battery when the generator isn't charging, such as when the engine stops or the generator dies. Since the generator has the ability to put out 10 to 15 amps of current, with no regulator in the system it would boil a battery in short order if the engine ran, say, all day long.

Tractor manufacturers minimized excess current going to the battery by means of a resistor in the generator's field circuit, to lower output of the generator, and they decided to put the resistor on the light switch and they gave control of the resistor to the tractor operator. My LA's generator didn't have a light switch, and happened to be wired for full generator output all the time. Fortunately the engine doesn't run very well, so I think the battery isn't ruined....

The light switch has positions 1, 2, and 3. At the "1" position, the resistor is in the circuit so the generator puts out low current, maybe 4 or 5 amps. The "2" position takes the resistor out of the circuit so the generator puts out full power, maybe 10 to 15 amps. You'd use this if you were just running the tractor for a short time, so the battery could get recharged quickly. The "3" position turns the lights on, so whenever the lights are on, the generator is still putting out full power but some of it is powering the lights so the battery doesn't get full power..

Manufacturers in the mid- to latter-40s I believe started putting voltage regulators on tractors so the output from the generator was automated and more regulated than a system with only a cut-out relay and manually switched resistor.

I recently bought a resistor/light switch and installed it. This first photo is the switch I bought. The resistor sits on the top of the switch (white porcelain cylinder with resistor inside). There's also a fuse on the bottom to protect the light wiring.

Monday, July 22, 2024

1936 John Deere BO Radiator Curtain Fabrication

The very early model B tractors came with a canvas curtain on the front of the radiator to regulate airflow through the radiator. The main reason for this is because the cooling system didn't have a thermostat common to all internal combustion engines these days. This BO's engine is called "All-Fuel", and it runs on both gasoline and distillate (i.e., kerosene). You'd start the cold engine on gas from a small tank behind the main fuel tank, then when it was warmed up, you'd switch to distillate, which was a cheaper alternative to gasoline back then. Distillate needed a hot engine to burn well, and the curtain was the solution at the time. In order to get the engine to operating temperature quickly, the curtain would be pulled down over the radiator so the engine coolant would warm up quickly. There was then a roller at the top of the curtain to crank up the curtain to regulate coolant temperature. Later model John Deeres used steel shutters that were controlled by a rod back by the operator (then even later by thermostat), making it so the person didn't have to dismount the tractor to adjust the airflow. I don't know when shutters were discontinued but I'd guess sometime in the late 1950s, when they went to more conventional means of temperature control.

Today's project is to make a radiator curtain. My tractor fortunately came with most of the hardware. My previous 1937 BO didn't have this hardware. The main components for the curtain are a radiator guard (the mesh screen), upper curtain roller, lower curtain clips and spring, and guard spacers. I don't have the spacers so will need to make them, but they are just a standoff to hold the radiator guard 1/4" away from the radiator. Below are the components.

Friday, July 19, 2024

1941 John Deere Model LA New Acquisition

It's been how long since I bought a tractor? Six days? Yup. And I just bought another one? Yup. But there were extenuating circumstances. Really. I got in touch with the previous owner of the 1936 BO tractor I'd just bought last week to line up a time to pick up a few spare parts he had. He said to come on over. I did, and after he showed me the parts, I asked if I could see his other tractors. He's got only John Deeres, an AR, an LA, and a B. He said he really needed to get rid of the LA, and he said these grave words, "It would make a great parts tractor for someone." Huh? Parts tractor? It's way too nice to be a parts tractor. So I asked what he wanted for it. Five hundred bucks. Huh?.... I'll take it! So I went home, hooked up the trailer, and went back to pick it up.

Monday, July 15, 2024

1936 John Deere Model BO First Repairs

It never seems to take long for me to do some fiddling on a new-to-me tractor, even though I'm in the middle of fixing the hood on my Ferguson TO-35. That project has just got to wait, since I have a new favorite toy to play with.

Today's first job was to fix the clutch rod. Someone in the distant past thought it was a good idea to weld an iron pipe nipple onto the rod, I presume for strength. One big problem was that in doing so, they made the rod un-adjustable for length. They also welded the pipe to the cast steel clevis on the end of the rod. That's also not good. My job was to fix the mess... Oh yeah, and straighten the rod.

Friday, July 12, 2024

1936 John Deere Model BO New Acquisition

By now I should know not to go to tractor shows. They're dangerous. Yes, I bought yet another tractor today (7/12/2024). But it was a good deal. The gentleman I bought the tractor from was a co-worker of mine from way back in the 80s and 90s. I'd bought a 1950 John Deere BN with a front loader from him around 1994. That tractor is long gone but in the last few years I'd reconnected with the gent through a local tractor club I'd joined several years ago. Recently he had been making comments occasionally that he wanted to sell this tractor and I took note. Well, today was a tractor show and he had the tractor at the show. It had died shortly after he got it off the trailer at the show and it didn't want to start again. I jokingly asked what the broken-down tractor was going for today. He said, "$2,500 show special." Later he threw out some other numbers. Sometime in the afternoon I told him I'd like to buy his tractor, and he seemed surprised that I was actually interested. So the deal was made. I came back home and picked up my trailer, then drove back to get the tractor. I put 180 miles on my truck in the four trips down and back from the show. Here are the photos of the tractor.

Saturday, July 6, 2024

Sleep Number Bed FlexFit Smart Mattress Top Magnetic Cover Repair

Anyone who has one of these Sleep Number FlexFit Smart adjustable beds probably knows what this posting is about. The mattress cover has magnetic pucks that correspond to steel pucks fastened to the bed base. Since the base is adjustable, the mattress needs to somehow "adhere" to the base so it doesn't just slide around, so Sleep Number used these strong magnets embedded in the mattress cover to attach to the base pucks. Problem is, the mattress cover that the magnetic pucks are attached to is very flimsy, and over time the magnets pull out of the cover and leave gaping holes. I found multiple postings online of other folks having the same issue, and their recourse was to pay Sleep Number between $250 and $1000 to fix it. Sleep Number does not warranty this issue (shocking) and I'm cheap (also shocking), so I decided to try and fix the thing myself rather than buy a new mattress cover. Below is a photo of one of the blow-outs.

Thursday, July 4, 2024

1965 International 140 Headlight "Fix"

I put quotes around the word "fix" because it's not really something that is broken, but is more of a visual enhancement on the tractor. You see, when International Harvester came up with the goofy Model 1000 one-arm loader, they had to come up with a way to move the right front headlight out of the way of the loader lift cylinder and arm. They made a nifty bracket that moved the headlight in and up. Problem is, they only moved the right headlight, so the left headlight sits lower than the right one and it makes the tractor look even goofier than it normally does with its offset engine and one-arm loader. I think now would be an appropriate time to use the word cockeyed...

Tuesday, May 7, 2024

1949 Ferguson TO-20 Generator and Regulator Repair

I figured it was time I looked into the charging system on the tractor. It had a dead 6 volt battery in the compartment when I bought it so I was pretty certain the electrical system wasn't too far out of order. I pulled the generator and regulator off the tractor and took them to the bench. The generator didn't look too terribly bad in where the three brushes reside, but two of the three brush holders were stuck. A little oil freed them up. This first photo below shows the side with one brush. It's pretty clean in there.

Saturday, May 4, 2024

1949 Ferguson TO-20 First Wash in Decades

Ok, so it wasn't really a "wash". I used a pressure washer. The tractor is still wet in the 'after' photos but it did make quite a difference...

Thursday, April 18, 2024

2015 Lincoln MKC Front Wheel Bearing Replacement

This isn't something I usually write about but in this particular instance I would like to get down in words the supposedly simple task of replacing a front wheel bearing that went south in a spectacular way. Over the past several weeks/months I've noticed a noise coming from the front of the Lincoln that has every indication of worn front wheel bearings. Ok, now it's time to see how much of a job this is, so I visit YouTube to see how everyone does it. They make it look so easy. Off to the Jungle website to find replacement bearings and a nifty bearing puller/installer setup so I can do the job on the car. Mistake number one, don't buy wheel bearings from Amazon, but more on that later.

I started on the driver's side, no particular reason why. After removing the wheel/tire, the first order of business is to remove the brake caliper and hang it up and out of the way. Next is the axle nut. It's tight. Very tight. A pipe on a couple wheel studs and a 24" breaker bar on the nut is what it took to remove it. The rotor can also come off now, along with the dust shield on the back side of the rotor.

Monday, March 18, 2024

1985 Cushman Truckster New Brake Master Cylinder

I bought this Cushman May of 2022 and it has had a brake master cylinder leak for who-knows-how-long, certainly years before I got it. I figured it was time to fix it. Needing to move the beast to the garage, the engine did not want to start. I cleaned the points. I checked the spark at a plug wire. I made sure the fuel pump was pumping. I cleaned the points again. I bypassed the coil resistor. I checked for voltage to the coils. I put in more gas. I checked the points again, and yep, still a spark. Then out of the blue, the thing started up. Who knows what the problem was. But during that time of troubleshooting, I had to push the Cush out of its hole in the shed, and in doing so, I noticed one of the dump bed hinges seemed a bit off. Ok, add that to the list of things to do today. Once I got the engine running, I drove to the front of the garage and lifted the dump bed. Yep, that is a broken hinge.

Thursday, February 22, 2024

Starting Work on the "Lawn Ornament" 1949 Ferguson TO-20 and First Start

With the 1958 Ferguson TO-35 back together, running, and moved out of the garage, there was a big hole just waiting to be filled, so I pulled the TO-20 lawn ornament in to begin the task of getting it running after who-knows-how-many-years of sitting neglectedly (is that a word?). Well actually I didn't pull the tractor in, my wife and I pushed it into the garage, as, you know, it doesn't run.

Tuesday, December 26, 2023

Epos Triple Date Moon Phase Chronograph, Valjoux 7751 Movement, Minor Adjustment

I don't do much tinkering with watches anymore since I have Familial (or Essential) Tremor. As the name implies, it causes shaky hands and is passed down from parent to child. Lucky me. Anyway, this Epos watch was bought in 1999 (for a whopping sum at the time of $697) after we'd paid off our house loan. It was a time to celebrate and my wife and I each decided to splurge on something nice. This is what I chose to buy. It had been having minute-counter issues for a number of years. When the chronograph was started, the central seconds hand would go round-and-round as it should but the minute counter would haphazardly either count or not count up the minutes (and since the hour counter was tied to the minute counter, its movement was also intermittent).

I didn't wear the watch much lately because I'd gotten other nicer watches over the years but I pulled the Epos out a few days ago to wear it. That's when I decided to try and fix the problem. It is not a small task to delve into an automatic chronograph movement, and it is compounded immensely by both shaky hands and the fact that this chronograph is additionally complicated with a 24-hour pointer, triple-date (day/date/month) functions and moon phase. I'd watched several videos on YouTube prior to taking the plunge, so I figured I knew pretty much what the problem was and how deep into the watch's bowels I had to go.

Monday, December 18, 2023

Old Barracuda's Old Wiring Woes

I hopped in the '66 Barracuda Formula S at church one night in the dark after instrument practice and something strange happened. I turned on the headlights and very soon after I started driving, the dash lights went out and the under-dash "map" light came on. As an added bonus, the two C-pillar dome lights no longer worked, as I'd found out since I was fiddling with the headlight dimmer switch to try and get the map light to go off. Get this, all three map/dome lights are controlled by the headlight switch - it makes no sense why one light would be on steady and the other two won't turn on. I figured it wasn't a big deal to drive home with no dash lights, and they did actually come on (and the map light went out) about halfway home.

Everything's fine, right? Apparently not. When I got home my brother texted me and said he saw no taillights or brake lights when I drove away from church. Hmm. Well at least they probably came back on when the lights "fixed" themselves on the way home. So, today I started digging into the 58-year-old dash wiring (the car was built November 1965). I wasn't sure what would cause this issue, so I started at the headlight switch. The easiest way to get to it was to pull the instrument cluster. It's not a terrible job but it isn't trivial. The steering column also had to be lowered to get the dash out.

Sunday, November 26, 2023

,,, And Then There Were Nine ...

It happened sooner than I expected. In fact, I hadn't expected this to happen at all. I brought home another tractor. And this one is a real doozie. It's a 1949 Ferguson TO-20. Rather than try to explain what I bought, here's a photo from the seller's ad on Craigslist. I know, it's a real peach.

Monday, October 30, 2023

1965 International 140 Industrial Tractor First Repairs

10/30/2023

As good as this tractor looks and runs, it still needs repairs right off the bat. Two issues that I found today are a non-operational hour meter and a broken seat track. The hour meter comes first.

Sunday, October 29, 2023

1965 International 140 Industrial Tractor with a Model 1000 One-Arm Loader

How many days has it been since I lamented over buying yet another tractor? Um, thirty-three. Yep, I bought another tractor yesterday. Uh-huh. But I couldn't pass up this one. It was just too quirky. Here, have a look for yourself.

Saturday, September 30, 2023

1951 Baird Beaver - New Front Tires and Implement Lift Repair

The front tires on this tractor are in sad shape. Holes in the sidewalls kept me from pumping them up very much. I ordered two new tri-rib tires off the net and today is the day to install them. With the wheels being a two piece design. I thought it would be a simple matter of removing the bolts, splitting the halves, and getting the new tires on. Nope. Firstly, the bolts fought me the whole way. One problem is, the head side of the bolts (screws?) have a slot for a screwdriver, so I couldn't use a wrench on that side. Secondly, the nuts were so tight on the threads that even with a vice-grip clamped to the screw heads I barely got the nuts off with an impact driver (I actually broke an adapter too). Once the bolts were removed and the old tires were off, I noticed both wheels had rust holes. Bummer.