I purchased this Shopsmith (abbreviated SS) in January of 2020 but I am just now getting around to putting it on my blog. It is in very nice condition and appears to still be wearing its original paint. The motor is a different color but these early machines didn't come standard with a motor. It is an AO Smith motor, which seems to be what most of these older Shopsmiths are outfitted with. The base is a heavy, home-made wood affair with small steel casters. The SS didn't come with a base from the factory, so the new owner would have to make their own.

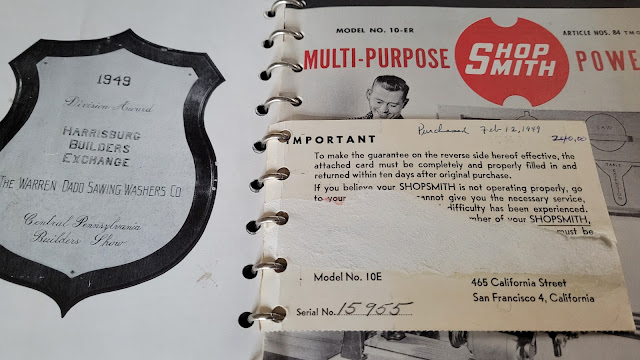

As shown in the above photo, it came with several accessories, namely a 12-inch sanding disc, 7-inch faceplate, circular saw table with fence, extension and miter gauge, wood lathe screw center, lathe tool rest, drill press Jacobs chuck, variable speed attachment, five W. Marples "cast steel" lathe tools, and a "Jeep" binder with a bunch of literature including the original guarantee card and packing list, a 10ER manual, several pamphlets from SS named Shop Notes and Shop Shavings, and a couple accessory manuals.

The Shopsmith came out in 1947, was manufactured by Magna Engineering in California, and their first model was called the 10E (the E standing for Experimental). In 1949 the model 10ER (Experimental Revised) came out and had several updates from the 10E. In 1953 the Mark 5 came out (and many years later the Mk V), which was a fairly radical update to the tool, but I won't be going into any of those details here.

This next photo shows the SS in the drill press orientation.

This next photo shows how the 10E's plywood extension was used. The two posts poking out of the plywood extension were to hold the 10E fence. The 10ER fence that came with my SS doesn't have the two holes to mount on the wood extension.

Below shows the Variable Speed Changer instructions.

I really didn't do much with this tool in the three years I've owned it, until the last couple of weeks when I decided to try my hand at turning a bowl. It's really the first time I've made anything of substance on a wood lathe. I used a chunk of apple tree I'd cut from my daughter's back yard several years ago, and had wrapped the wood chunk in cellophane so it would dry slowly. Unfortunately it still had some cracks when I took it out of the wrapper a year ago. I only had a face plate to mount the wood to, which wasn't ideal. When the bowl was finished, I added two sets of three lines on the bowl, to give it a little more character.

After making the bowl I thought I'd sell the SS because the bowl-making experience wasn't that great. The issue could have been because the wood blank wasn't flat against the faceplate. It was screwed tightly to the faceplate but there may have been a bit of room for flexing. Anyway, I put the SS on Craigslist and I then started looking for a replacement wood lathe but couldn't find anything I was willing to pay the amount people were asking, so I decided to keep this SS.

I then decided I'd make an adapter so I could mount a small Atlas threaded faceplate I had laying around. It has 1"x8tpi threads, which is fairly standard on small wood lathes. Below is a photo of my first attempt on the right, in which I didn't take into account that the faceplate needed a shoulder to mate against. The adapter on the left is the second try, which works well. The faceplate now runs true. Using the old adapter, the faceplate wobbled a little.

A couple days ago I picked up the below four-jaw scroll chuck from Amazon for $100.

Below is the cedar platter that produced the above mess, and another photo further down showing the original cedar plank that the bowl came from. My dad had split the plank off an old growth log in the woods at their Bainbridge Island home in the 1970s. Yes, I've kept that plank all these years and a good portion of it is still in the basement.

I counted 119 growth rings from one side of the platter to the other. There's no telling how old this cedar tree was when it died, but the snag was hollow in the middle when a forest fire burned it long ago on the island, which gives the sides of the platter the dark coloring. The darker side of the platter was the outside of the snag, while the lighter-charred side of the platter was the inner part of the snag.

I guess I've gotten on a roll with bowl-making. This is a few days after I made the cedar bowl, so it's my third bowl. I started with a piece of burl wood I picked up at a garage sale for a buck or two. It's such an odd shape that I couldn't do much with it, but I was able to carve out a very small bowl. It is four inches in diameter and two inches tall.

There was one casualty on my first bowl-making attempt. Yes, I know that my Marples roughing gouge is not the right tool for bowl turning, but I don't have a bowl gouge so I make do with what I have. The below photo shows the handle glued back together but I still need to pare down the end so the ferrule can fit again. The break is nearly invisible but a three inch chunk of the handle broke off one side. Only time will tell how well the glued handle will hold up. And look, three carved lines in two places on the handle. It must be a thing. I just now noticed that while composing this blog posting.

And a week or so after the above photo was taken, the gouge is repaired in the below photo. Turning down the end so that the ferrule would fit was easy on the lathe. I chucked the back end of the handle in the 4-jaw chuck and ran the other end into a dead center, which worked fine and the gouge is operational again, albeit a half an inch shorter.

This next photo is of all the lathe tools I've acquired over the years. Five Marples (came with this SS), three Craftsman, three Disston, and one Big Bertha D.R Barton monster (to me) gouge. I'm not sure where these other tools came from. They seem to just appear in the basement....

No comments:

Post a Comment